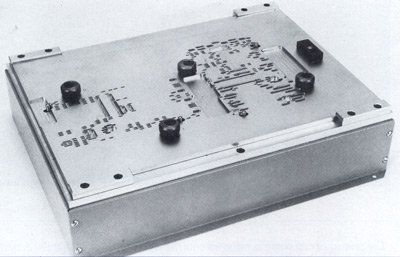

Multipoint PCB Assembly Machine

Eliminate costly PCB insertion rework by using the Manix Multipoint assembly system. Simply insert the component into the circuit board, depress the foot pedal, and the component will be either cut or cut and bent for good mechanical retention. Stop part fallout during PCB transport or costly post solder rework due to component lifting during wave soldering.

Multipoint PCB Assembly Machine

OVERVIEW

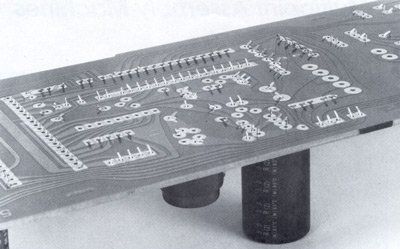

Dislodged or floating components due to transport or wave soldering is eliminated by using the Multipoint. Good mechanical retention ensures good electrical connection. Each Multipoint is designed around your specific PCB. The system is fabricated to the hole layout of your PCB. Operators simply install a component into the PCB, depress the foot pedal, and the component leads are either cut or cut and bent over for strong retention into the PCB. Multipoint systems are available as stand-alone or incorporated into an assembly line.

PRODUCT FEATURES

Repeatable results eliminates rework.

Component sensing and polarization units are available.

Choose cut and bend or cut only systems.

Part lifting during wave soldering is eliminated.

Part fallout during transport is eliminated.

Conveyorized units speed assembly time.

Foot pedal reduces operator fatigue

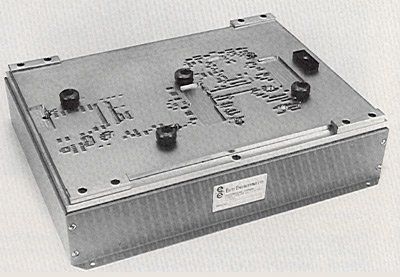

SPECIFICATIONS

Speed: Up to 720 component insertions per/hr.

Air: 80 psi required

Actuation: Foot pedal

Size: Unit dependent

Weight: 35 lbs.

Part Sensing: Optional detection of proper placement

Polarization: Optional sensing for orientation

Conveyorized: Optional unit interfaces with assembly line.