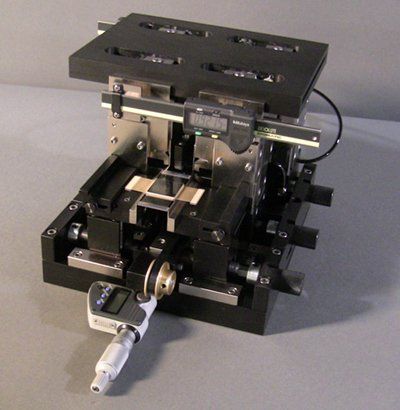

FP-1500 AUTOMATIC FLAT PACK SYSTEM

Forming and cutting of flat pack components can be troublesome. Mishandling of flat pack components can be costly. The new FP-1500 automatic adjustable flat pack forming and cutting system eliminates these problems. Simply place an unformed Flat Pack onto the centering station, depress the start button on the PLC controller, and the system will do the rest. The component to be processed will be transported through the various tooling stages. It will be formed first on two sides, retaining the tie bar through transport. The component will then be cut to length and transported back to the home position for other side cutting and forming or replacement to a new component.

FP-1500 Automatic Flat Pack System

OVERVIEW

Form and Cut two sides of a flat pack component to a reflow configuration with the new automatic adjustable FP-1500 from Manix Manufacturing, Inc. A motorized flat pack component transport system guides the component through the various stages of forming and cutting. Controlled by a PLC, the system can store valuable information which can be recalled time and time again. Component details such as part number and adjustment settings sit idle in a library until that program is recalled.

The FP-1500 is fully adjustable. Component body size, overall cut length, footpad, stand-off height, and body to first bend can easily be changed by a simple turn of the micrometer or thumbwheel. Lead thickness and radii are easily changed in less than 5 minutes by quick change inserts.

LED lighting, viewing doors with interlock switches, and AIRCLEAN, a system to effectively remove off cuts or tie bars from the tooling into a collection bin are all included in the system.

PRODUCT FEATURES

Form and Cut two sides of a flat pack component simulataneously.

Automatic motorized component transport eliminates operator handling.

Fully adjustable tool changes parameters in a matter of minutes.

PLC controller stores valuable component information.

Micrometer setup software included.

AIRCLEAN removes off cuts and tie bars and deposits waste into a built-in collection bin.

Viewing windows and doors with interlocks provide maximum safety.

LED lighting offers maximum viewing.

SPECIFICATIONS

Size: 19.5”W X 20.5”D X 25.5”H

495mm X 521mm X 648mm

Weight: 250 lbs. / 114 Kgs.

Air: 80 psi dry air required.

Connection: ¼” or 6mm tube.

Electrical: 110/250 VAC single phase.

Switching power supply.

Controls: PLC with embedded software.