Robotic Integration Lead Forming and Cutting

Axial, Radial, Flat Pack, and even IC’s can be easily inserted onto a PCB or into a housing, via a robot or pickup head, using our stand-alone lead forming and cutting systems. These systems are designed for factory automation and can be integrated into a full production line in a matter of minutes. Whether the components are loose, tape and reel or ammo pack, Manix has a system for you. All components are either cut and formed, formed only or cut only to your exacting specifications and presented for pickup.

Robotic Integration Lead Forming and Cutting

OVERVIEW

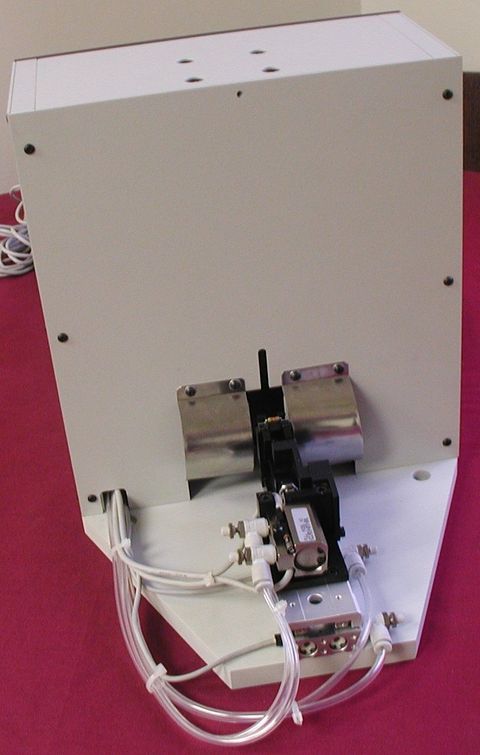

Manix has developed a range of stand-alone machines which easily mount onto your new or existing robotic assembly line. These systems can be actuated on demand via your software. Separate inputs for feeding, die actuation, and component presentation are standard. Components are presented at either the cut and form station with pickup head clearance or a shuttle table with optional grippers to a desired location.

PRODUCT FEATURES

Shuttle table presents component for pickup.

Separate inputs control the feeding, die actuation and component presentation.

Cylinder stroke sensors make integration easy.

Fully pneumatic systems allow for quick setup.

SPECIFICATIONS

Activation: On Demand, Pneumatic.

Rate of Forming: Up to 1,200 parts per hour.

Dimensions: Application dependent.

Weight: Application dependent.

Air Required: 80 psi.

Paint: Powder Coat, off white.

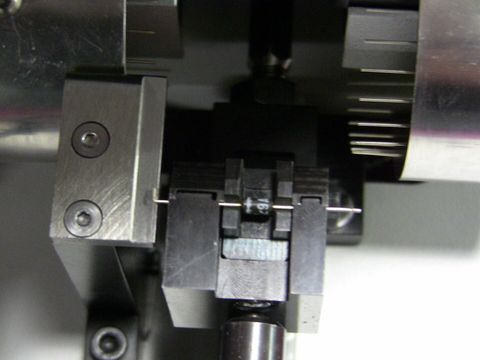

Tooling: Precision ground tool steel.