Adjustable Cutting and Forming Dies

Flat pack cutting and forming has never been made easier than with the many flat pack adjustable dies offered by Manix. Some or all of the critical dimensions of cutting and forming can easily be changed to suit your next requirement. Eliminate purchasing fixed dies specific to your application with the range of Manix adjustable dies. Each die mounts on the FP-5 Pneumatic Press in a matter of minutes. In some cases, a software program is offered to ease in set-up.

Watch our Video for FP-1MAS-2 SINGLE SIDE TWO STAGE ADJUSTABLE DIE

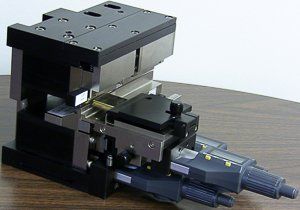

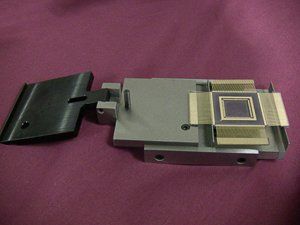

FP-1MAS-2 SINGLE SIDE TWO STAGE ADJUSTABLE DIE

OVERVIEW

Cut and form flat packs one side of a time to a reflow configuration with the unique FP-1MAS-2. It is the only die available that can change body size, overall cut length, lead thickness, top and bottom radius, body to bend, footpad size, and standoff height in a matter of minutes.

Digital Micrometers and quick change inserts make for an easy changeover. This two stage die first forms the component to reflow, then cuts the leads to the desired length. A linear slide ensures component integrity while minimizing handling. The die includes a removable component holding nest, ensuring component integrity. All Manix dies include forming clamps, which eliminates lead to body fractures.

PRODUCT FEATURES

Hardened cut/form precision ground tool steel elements.

Easy to adjust digital micrometers.

Adjustable component holding nest for ease of handling.

Software program for micrometer setup.

Electroless nickel plating, and hard coat black anodizing ensure long tooling life.

SPECIFICATIONS

Size: 7.5”L X 12”W X 5.5”H

190mm X 305mm X 140mm

Weight: 17 lbs, 8 kgs.

Forming Specifications: Available on PDF Brochure

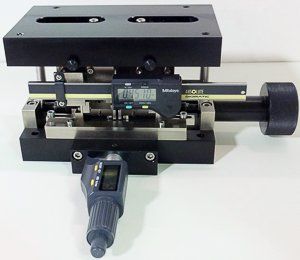

FP-2MAS TWO SIDE ADJUSTABLE DIE

OVERVIEW

Cut and form flat packs two sides simultaneously to a reflow configuration with the FP-2MAS. Body size, overall cut length, standoff height, lead thickness and top radius can be easily changed.

A linear scale sets the overall cut length, while a digital micrometer sets the standoff height. Quick change insert anvils allow for different lead thicknesses and top radius. A precision lead screw adjust for body size and a unique centering device ensures the component is formed equally.

PRODUCT FEATURES

Hardened cut/form precision ground tool steel elements.

Easy to adjust digital micrometer and linear scale.

Quick change lower forming anvils adjust for varying lead thickness and top radius.

Centering device ensures component symmetry.

Electroless nickel plating, and hard coat black anodizing ensure long tooling life.

SPECIFICATIONS

Size: 10”L X 9”W X 5”H

254mm X 229mm X 127mm

Weight: 14 lbs., 6.4 kgs.

Forming Specifications: Available on PDF Brochure

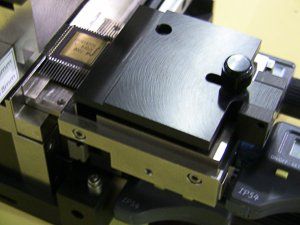

M805 FP-1MASD SINGLE SIDE ADJUSTABLE DIE

OVERVIEW

Cut and form flat packs one side at a time to a reflow configuration with the M805 FP-1MASD die. Body size, overall cut length and standoff height can easily be changed by two micrometers and an adjustable component holding nest.

Footpad, lead thickness and lower radius remain fixed, while the other dimensions are easily changed using digital micrometers or by changing inserts. Simply input your dimensions and you are ready to go!

Digital micrometers are used to adjust the overall cut length and the standoff height. Quick change insert anvils allow for different lead thicknesses and top radius.

PRODUCT FEATURES

Hardened cut/form precision ground tool steel elements.

Easy to adjust digital micrometers.

Adjustable component holding nest for ease of handling.

Electroless nickel plating, and hard coat black anodizing ensure long tooling life.

Lower cost offers maximum return.

SPECIFICATIONS

Size: 8.5”L X 6”W X 6.5”H

216mm X 152mm X 165mm

Weight: 11 lbs., 5 kgs.

Forming Specifications: See PDF below.

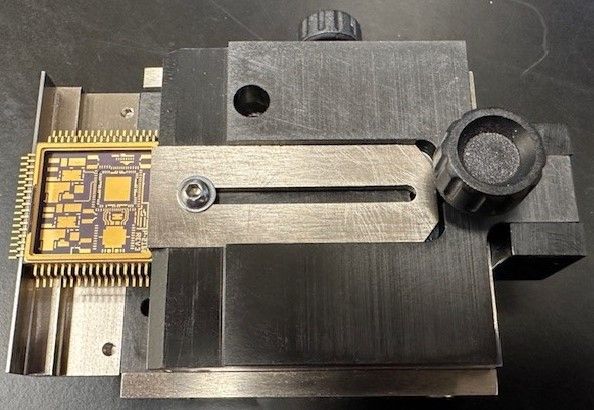

FP-1MAS-CD SINGLE SIDED ADJUSTABLE CUT ONLY DIE

OVERVIEW

Cut flat pack components leads to your exact specification with the FP-1MAS-CD cut only tool. Adjustable for body size, lead thickness, and cut length, this tool sets up in a matter of minutes. A digital micrometer and adjustable component holding nest make changes easy.

A tooling clamp eliminates any damage at lead egress. Component leads are cut accurately each and every time due to the precision ground tool steel cutter.

PRODUCT FEATURES

Hardened cut/clamp precision ground tool steel elements.

Easy to adjust digital micrometer.

Adjustable component holding nest for ease of handling.

Electroless nickel plating, and hard coat black anodizing ensure long tooling life.

SPECIFICATIONS

Size: 10.5”L X 4.5”W X 6.5”H

267mm X 114mm X 165mm

Weight: 10 lbs., 4.5 kgs.

Forming Specifications: