Cutting and Forming Dies

The Manix range of lead forming and cutting dies are available for Axial, Radial, LEDs, Hall Sensors and other leaded components. Most of the dies can mount for either single or automatic actuation. Dies can be purchased either fixed or adjustable for center spacing, cut lengths and body to bend distances. Most Manix dies clamp the leads conforming to all the stringent MIL-SPEC standards.

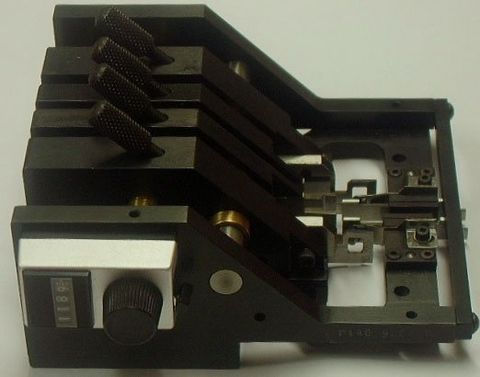

AXIAL DDJ SERIES

OVERVIEW

Three different lead screw dial adjustable dies are available for automatic or manual cutting and forming of axial component leads to a 90 degree bend. The DDJ-1 and DDJ-1R accepts up to 0.032” (.8mm) lead diameter, while the DDJ-1HDC from 0.033” (.84mm) to .060” (1.5mm) lead diameter. The DDJ series of dies can mount on the automatic/manual CF base or the single stroke SS-1A. Each die clamps the leads eliminating lead to body damage. After clamping, the component is cut to length, then formed 90 degrees to the set lead spacing.

PRODUCT FEATURES

Dials set lead spacing and cut length.

DDJ-1 uses spring formers for the bend.

DDJ-1R uses roller formers for the bend.

DDJ-1HDC processes thick leads including troublesome steel.

Linear stroke ensures repeatable cuts and bends.

Component nomenclature can be positioned for easy identification and quality assurance.

SPECIFICATIONS

See Brochure

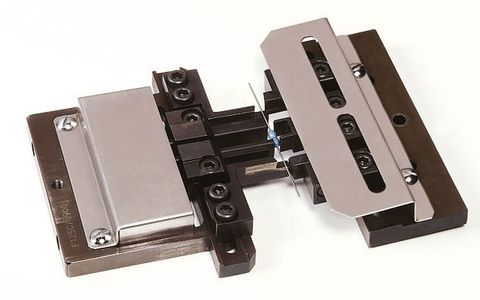

AXIAL ADJ SERIES

OVERVIEW

Two manually adjustable dies are available for automatic or manual cutting and forming of axial component leads to a 90 degree bend. The ADJ-1 accepts up to 0.032” (.8mm) lead diameter, while the ADJ-2 from 0.033” (.84mm) to .060” (1.5mm) lead diameter. The ADJ series of dies can mount on the automatic/manual CF base or the single stroke SS-1A. Each die clamps the leads eliminating lead to body damage. After clamping, the component is cut to length, then formed 90 degrees to the set lead spacing. Lead forming dimensions can easily be changed by manually moving the tooling elements to the correct setting.

PRODUCT FEATURES

Moveable tooling elements adjust for lead spacing and cut length.

Both dies mount on either the SS-1A or CF machines.

Forming clamps ensure Mil-Spec quality of form.

Hardened tool steel cutters ensure long cut life.

Linear stroke ensures repeatable cuts and bends.

Tooling drift is eliminated by secured tooling elements.

SPECIFICATIONS

See Brochure

AXIAL FIXED AND ADJUSTABLE DIES

OVERVIEW

Stand-off, snap-in, and vertical form dies are just some of the other dies available for either automatic or single stroke lead cutting and forming. All dies clamp the leads prior to cutting and forming, eliminating lead to body damage. Military stress relief and SMT gull wing dies can be purchased either for fixed or adjustable dimensions.

PRODUCT FEATURES

Right angle cut and form with stand-off or snap-in.

Vertical cut and form without or without stand-off or snap-in.

SMT gull will from standard axial component

Military stress relief with or without adjustability.

Right angle lock-in forms with stand-offs.

SPECIFICATIONS

Model “C” Right Angle Only

Model “E” Right Angle snap-in/stand-off

Model “G” Right Angle stair bend stand-off

Model “H” Right Angle stand-off

Model “I” Vertical stand-up w/double radius

Model “J” Vertical stand-up form only

Model “L” Right Angle lock-in w/stand-off

Model “O” Right Angle stress relief

Model “P” SMT gull wing

Model “Q” Vertical lock-in w/stand-up

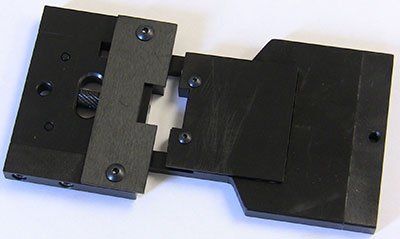

SS-11 MULTI-PITCH CAPACITOR FORMER

OVERVIEW

The SS-11 Radial Capacitor "Stairway" Die accepts the four most common capacitor centers and cuts and forms to a snap-in or stand-off configuration. The SS-11 reduces assembly cost by eliminating post solder trimming (leads are cut to a uniform 0.060" protrusion), eliminating component fallout or tilt, and raising capacitors off of the PCB by 0.125" to eliminate the installation of costly spacers. An unskilled operator can process between 1000 and 1800 pph. The SS-11 is comprised of theSS-11D die and theSS-1A pneumatic base machine.

PRODUCT FEATURES

Cut and Form Capacitors with .1”, .2”, .25”, and .375” Lead Pitches.

Adjustable Lock-In Feature Adjust to Hole/Lead Diameters.

Trims Leads to 0.060” Below PCB.

“Toe-In” Crimp Locks Capacitors in PCB.

SS-11D Plus SS-1A Base Machine Equals SS-11 System.

SPECIFICATIONS

Lead Pitches: .1”, .2”, .25”, .375”

Stand-Off Height: .125”

Lead Protrusion: .060”

Maximum Lead Diameter: .034”

Crimp: Adjustable for lead to hole diameter.

Air: 80 psi.

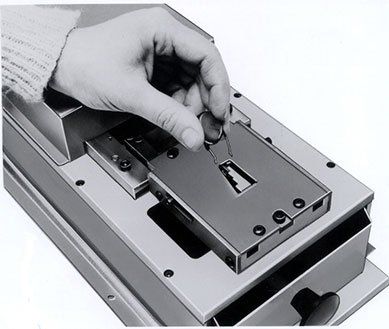

RADIAL LEAD FORMING DIES

OVERVIEW

Cut only, form only, or cut and form all types of radial components with the range of Manix single stroke radial lead forming dies. Transistors, Capacitors, LED’s and even Hall Effects can be preformed using dies manufactured by Manix Manufacturing, Inc. Dies can mount on the SS-1A single stroke base machine or the automatic CF system. Both systems include a foot pedal for single input operation. Dies are built to your exact specifications.

PRODUCT FEATURES

Dies are manufactured to meet your forming specifications.

Dies mount on SS-1A single stroke machine.

All dies are manufactured of hardened tool steel.

Cut only, form only, and/or cut and form dies are available.

Dies for transistors, capacitors, LED’s, hall effects.

SPECIFICATIONS

See PDF for complete specifications